By Brian Billy1, Dr. Muniram Budhu2, and Dr. Robert Casavant3

Background

The City of Patagonia, AZ is located in Santa Cruz County and approximately 60 miles SE of Tucson, AZ, at an elevation of 4,055 ft. The City has a population of 825 (2006 census). The town is located within the Sonoita Creek Watershed and is outside Active Management Areas, which are designated by the Arizona Department of Water Resources. In 2003 a multi-agency grant was approved for upgrading the existing wastewater treatment plant (WWTP) and to rehabilitate portions of the sewer collection system. The plant upgrade has improved the quality of effluent discharged to Sonoita Creek by decreasing overall nitrogen levels. The sewage line rehabilitation has decreased the amount of wastewater leaking into the regional aquifer, resulting in improved health and environmental conditions. The electricity provider for the city is the Sulphur Springs Valley Cooperative (referred to herein as Sulfur Springs).

Water

Supply, Pumping, and Storage

Supply, Pumping, and Storage

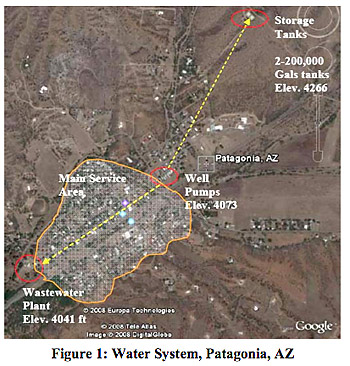

The City of Patagonia relies solely upon groundwater to serve its residents. Two wells, operated alternately and equipped with submersible pumps, are located within the center of town and supply water directly into the distribution system and to an upper storage reservoir. The static water levels of the wells vary from 15 to 30 feet below the land surface, depending on demand and time of year. The two recently-overhauled 30-hp submersible pumps are controlled by telemetered signals from reservoir water-level sensors. The pumps operate daily, for up to six hours, at a rate of 325 gallons per minute (gpm), which yield nearly 110,000 gallons per day (gpd). The upper storage reservoir consists of two 200,000 gallon underground tanks. When the pumps are on, in addition to pressurizing and supply water to the distribution system, they pump water to the reservoir. There is metering at the well head. The water is pumped upgrade at slope of 6.5% for 0.75 miles (see Fig. 1).

Treatment

Currently there is no well-head chlorination due to malfunctioning chlorinators. As a result, the water supplied to the system when the pumps are running is untreated. The city is in the process of identifying replacements or repairs for the well-head chlorination system. Presently, staff members add chlorine tablets manually to the storage tanks every few days. Residual chlorine levels are monitored to maintain compliance with Safe Drinking Water Act standards.

Distribution

Treated water is conveyed either from the storage tanks via gravity or by direct well pumping to the service area, which has 414 connections. The pressure in the uppermost portion of town is 65 psi and rises to 95 psi in the lower portion. Pressure reducing valves are used to regulate the pressure. Water from storage is conveyed to the service area utilizing the same pipe (8-inch main) that is used to transport it to the reservoir. The main distribution pipeline bisects the city’s business district, with laterals extending to various parts of the service area. The pipes range in size from 2 in. to 8 in. and are made primarily of ductile iron, Transite, and PVC. Leak detection is done by regular meter monitoring of flow at the well head and at points of individual use. Currently, there is no booster pump to outlying or high-elevation areas. One key issue that has been identified is malfunctioning check valves at the wells. The existing valves occasionally stick in the open position when the pumps turn off. This allows water to pass back through the check valves and back into the wells. Not only does water get lost from the distribution system back to storage, but there is potentially a condition of suction in the distribution system.

The treatment plant is located in the southwest part of the city at an elevation of 4027 ft on a 9.5-acre site adjacent to Sonoita Creek, within the 100-yr flood plain. The sewer system of Patagonia was constructed in 1965 under the town's "Sewer Improvement District One" project. The sewage collection system consists of 19,000 linear feet (lf) of 6, 8, and 10-inch gravity sanitary sewer pipes. Subsequent improvements to the system include rehabilitation of approximately 5,500 feet of the sewer lines and installation of an oxidation ditch for extended aeration wastewater treatment.

The treatment plant is located in the southwest part of the city at an elevation of 4027 ft on a 9.5-acre site adjacent to Sonoita Creek, within the 100-yr flood plain. The sewer system of Patagonia was constructed in 1965 under the town's "Sewer Improvement District One" project. The sewage collection system consists of 19,000 linear feet (lf) of 6, 8, and 10-inch gravity sanitary sewer pipes. Subsequent improvements to the system include rehabilitation of approximately 5,500 feet of the sewer lines and installation of an oxidation ditch for extended aeration wastewater treatment.

Collection / Conveyance

The city’s wastewater is conveyed to the plant via gravity and received at an average rate of approximately 420,000 gallons per day (gpd). During the peak season the flow rate increases to nearly 520,000 gpd. The system works efficiently and there have been no significant maintenance issues. The installed collection piping is a combination of concrete, vitreous clay, and PVC types.

Conveyance Treatment

The wastewater flows a horizontal distance of 3 miles at downward grade of 0.32% from the service area in a gravity-driven collection system. The overall system has a total design capacity of 110,000 gallons per day (gpd), However, on average the plant generates 60,000 gpd of effluent with 99-100% BOD removal. The influent is screened to remove large items and then passed through a grit chamber to remove the large colloidal particles. The wastewater is then lifted a vertical distance of approximately 10 ft and a horizontal distance of nearly 50 ft utilizing two 4-in. 10-hp grinder pumps that operate alternately. On average, the pumps operate 20 times daily for 15 minutes at 200 gpm. The plant utilizes activated sludge with an anoxic denitrifying chamber to ensure maximum nitrogen removal. The first process consists of a pre-anoxic basin where influent wastewater, return sludge from the clarifier, and nitrate-rich mixed liquor pumped from the effluent end of the aeration tanks are mixed together to form the liquor used in the digestion process. The process proceeds through a series of aeration tanks where the air is fed by 25 hp blowers to maintain a set level of dissolved oxygen and promote aerobic digestion. After passing through two separate aeration chambers the water is fed into a clarifier where the heaviest solids and microorganisms are allowed to settle out. The clarified water then exits through V-notch weirs and enters 3 separate chlorination contact zones where it is chlorinated, de-chlorinated, and then discharged into Sonoita Creek. The plant is fully automated and is equipped with a diesel back-up generator in case of power outages. The main energy consumption at the plant can be attributed to the blowers that run 24 hrs daily with one added blower needed during the summertime. The remaining processed sludge is passed through a belt press (see Fig. 2) and made into cake for transport to the city landfill.

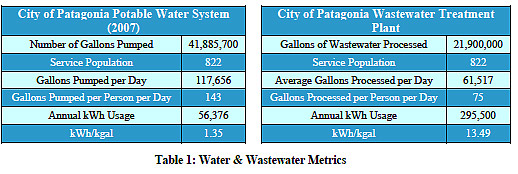

The system metrics are shown in Table 1. They were developed from utility billing records received from Sulphur Springs and the City of Patagonia. The amount of pumping was based on monthly data for both wells and then compared to the monthly billing records. These metrics were based on the year 2007 to obtain a snapshot of the city’s operations. Natural gas consumption data were not considered because these data were not made available.

Presented below are best practice recommendations and suggestions identified as part of our qualitative evaluation.

- Evaluate the balance between revenue and expenses.

- Understand how water and energy are utilized throughout the system.

- Review system plans, specifications, and records before considering upgrades/improvements.

- Secure operations and maintenance guides and training for park staff when new systems/components are installed.

- Evaluate all pumps, blowers, and motors for upgrade to either high-efficiency or VFD, as appropriate.

- Fully assess blowers operation and quantify how much energy they consume on average and during peak seasons.

- Repair/replace the malfunctioning check valves.

- Adequately ventilate or sunshield all electrical and mechanical equipment in warm weather.

- Utilize off-peak power usage strategies.

- Develop water audits and implement leak detection programs.

- Implement water budgets and rate structures.

- Create financial (or other) incentives for water customers to conserve.

- Adopt water-efficient codes and ordinances.

- Create water conservation education programs.

- Coordinate water production/delivery with treatment process capacity.

- Retrofit facilities with energy efficient lighting.

- Install chlorinators at the well locations.

- Reduce friction/energy losses in pumps, fans, pipes, valves, and production wells.

- Inventory and replace all non-functioning metering devices.

- Optimize treatment processes to reduce water and energy consumption.

- 1Graduate student (lead author), Dept of Civil Engineering and Engineering Mechanics, University of Arizona, email: bbilly@email.arizona.edu

- 2Professor, Dept of Civil Engineering and Engineering Mechanics, University of Arizona, email: budhu@email.arizona.edu, tel: (520) 621-2145

- 2Research Associate Professor, Dept of Mining and Geological Engineering, University of Arizona, tel: (520) 260-8826. Also 3Science and Research Manager, Arizona State Parks, email: rcasavant@azstateparks.gov

- For more information on the City of Patagonia’s WWTP, contact Rob Van Zandt, Arizona State Parks Development Programs Specialist, tel: (520) 988-0155, or Randy Heiss, City Manager: (520) 394-2220.

- Project Sponsor: Arizona Water Institute.

- Grant Partnering Universities and Agencies: Northern Arizona University, University of Arizona (contact Dr. Muniram Budhu), Arizona State Parks (contact Dr. Robert Casavant), City of Patagonia.