By Brian Billy1, Dr. Muniram Budhu2, and Dr. Robert Casavant3

Background

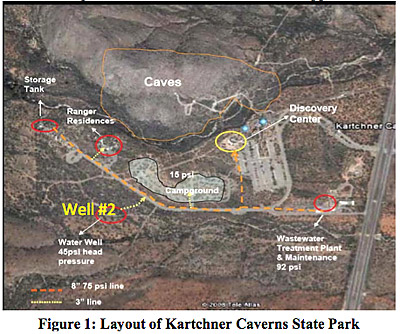

Kartchner Caverns State Park is located in southeastern Arizona, approximately 9 miles south of the town of Benson along State Route 90. The 550-acre park attracts over 200,000 visitors annually. The demands on the water and wastewater systems are based upon the influx of visitors to the caves, and on campground utilization. The peak visitation and water demands occur between the months of November and April. The largest constructed facility is the 23,000-square-foot Discovery Center that sits at the base of the cave inlet. It serves as the main collection area for visitors. The park has bathroom facilities located at the Discovery Center, the trailhead area, and at the main campground area. The park is equipped to handle day-use visitors, campers, and recreational vehicles (RV’s). Other notable facilities are the wastewater treatment plant (WWTP), maintenance area, ranger residences, and various offices. Overall groundwater levels within the parks have been steadily declining over the past 10 years and studies are in progress to evaluate when the wells that serve the park will reach non-sustainable levels.

Water

Supply & Pumping

Supply & Pumping

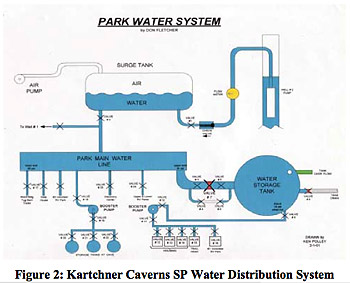

The sole source of water for the park is groundwater. There are multiple wells located within the park, but Well #2 is the only one that currently serves the park. The well is located at the southwest side of the park below the main campground area (Fig. 1). The average annual pumping for 2007 was measured at 2.3 million gallons (MG). The average daily withdrawal is 6,000 gallons per day (gpd) but can be as high as 20,000 gpd during the peak season and as low as 4,000 gpd. The water is pumped to the surface utilizing a 3-hp 480 V 3-phase submersible pump. The water distribution system (Fig. 2) is manually operated and requires that the pump be turned on every morning in order to fill the 3000 gallon storage tank (elev. 4732) located northwest of the well. The elevation difference between the well and the tank is 75 ft over a horizontal distance of 1800 ft (4% grade). Once the tank is full, the pump is turned off and the park utilizes the elevation head to drive the flow. If demand is high, the tank is filled first and the upper valve is closed. The park then serviced directly from the well. Metering for the potable water system is done only at the well site.

Treatment

TreatmentThe pumped water is treated at the well head, when the submersible pump is operating, prior to being conveyed to other parts of the system. A small dosing pump injects a chlorine solution from a holding tank that contains a solution of 20 gals of water plus 2 quarts of 12% sodium hypochlorite.

Transmission, Storage & Distribution

Groundwater is fed through the system via an 8-inch PVC main, with 2-inch and 3-inch PVC laterals. The system pressurization varies from 15-90 psi throughout the park. The area most prone to low pressures is the main campground area. The system has two booster pumps located near the ranger residences and below the water storage tanks. Backflow prevention devices and pressure reducing valves are located throughout the system to maintain pressure, meet demand, and protect the water supply. Wastewater Treatment Plant

The wastewater treatment plant (WWTP) at Kartchner is located at the southeastern portion of the park at an elevation of 4574 ft. The topography is such that all wastewater flows under the action of gravity to the WWTP. The wastewater comes from bathrooms, ranger residences, the campground uses (including showers), and the Discovery Center (Fig. 1). The park is also equipped with a dump station that consists of two 110 ft lanes (to accommodate RVs), two sumps, a wastewater tank, and a non-potable water source. The WWTP has a maximum operating capacity of 20,000 gpd, and processes approximately 2.1 MG annually at an estimated average daily rate of 6,000 gpd. Wastewater flows as high as 22,000 gpd have been recorded. However, it was deduced that the well’s flow meter may be faulty. Thus, this peak flow remains in question.

Collection & Treatment

The collection system operates solely under the action of gravity and delivers wastewater to a lift station. The station’s holding tank is equipped with baskets for segregation and removal of large waste, along with grit removal. The tank has two submersible 4 hp grinder pumps that alternately lift the water to the WWTP. The tank wastewater elevation is monitored by a mercury-type flow switch that controls pump operation. The control levels are set to stop all pumps at a low liquid level and start the first pump at a high level. The lift station moves the wastewater to the initial point where treatment begins. The WWTP plant is a Schreiber package plant consisting of two Bio-Reel treatment units. The Bio-Reel systems are housed in a reinforced concrete tank and operate in parallel. There is an anaerobic stage and an aerobic aeration chamber linked to a blower that infuses air into the system. The unit includes a large number of tubular spirals that are confined in a reel-like rotary cage, which provides for the growth of attached microorganisms (“bugs”) that breakdown wastewater products. The reel assembly is immersed in the reactor vessel and rotated by air. During rotation, air bubbles are trapped in the tubes, providing oxygen to the biomass while circulating the wastewater through the tubes. Within the anaerobic chamber the wastewater is introduced to the bugs. The nutrients are transferred to the biomass (adhering to the tube walls) for BOD reduction and ammonia (NH3-N) nitrification. The ammoniated compounds flip the ammonia into the nitrate stage and when it hits the aeration zone it converts from nitrite (NO2) to nitrogen gas and oxygen, the latter being consumed by denitrifying bugs. The processed wastewater is then fed into an effluent tank where it is collected and pumped to a mesquite orchard, adjacent to the plant, where it is used for irrigation. During periods of high-flow the effluent tank can be bypassed and effluent is discharged to two storage ponds. The park changed its permit with the Arizona Department of Environmental Quality and does not have to monitor wastewater contaminants. The processed sludge collects at the bottom of the Bio-Reel reactor vessel and is transported to a solid waste disposal facility about every 2 years. The plant has several diesel single-phase backup power units, in the event of power outages.

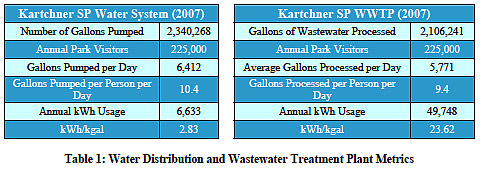

Table 1 show the metrics used in the analysis. The high kWh/kgal values for the WWTP can possibly be attributed to a faulty wastewater flow meter and the inability to quantify the amount of kWh attributable to the plant itself. According to park staff, the park is in the process of performing a systems audit and inventory to better understand the functioning of their system. The HVAC system’s chiller and boiler have been documented as being two of the biggest users of power. Diesel/gas usages were not considered because the data was not made available.

Table 1 show the metrics used in the analysis. The high kWh/kgal values for the WWTP can possibly be attributed to a faulty wastewater flow meter and the inability to quantify the amount of kWh attributable to the plant itself. According to park staff, the park is in the process of performing a systems audit and inventory to better understand the functioning of their system. The HVAC system’s chiller and boiler have been documented as being two of the biggest users of power. Diesel/gas usages were not considered because the data was not made available.

Presented below are best practice recommendations and suggestions identified as a result of our qualitative evaluation.

- Check manholes in the park to ensure they are not exposed to the open environment; remain free of large debris that might inhibit system flow.

- Ensure the system is not receiving and processing excessive storm water due to intrusion into the collection system.

- Obtain an accurate count of all systems that are drawing the most energy and determine accurate estimates of kWh usage.

- Assess the balance between revenue and expenses.

- Understand how water and energy are utilized throughout the system.

- Review system plans, specifications, and records before considering upgrades/improvements.

- Evaluate costs for different available water sources.

- Secure operations and maintenance guides and training for park staff when new systems/components are installed.

- Evaluate pumps, blowers, and motors for possible upgrade to either high-efficiency or VFD.

- Retrofit facilities with energy efficient lighting, using high-efficiency ballasts and bulbs.

- Install additional flow meters around the park to obtain an idea of where most of the water is being used and cut back on losses.

- Pressurize the system only when necessary (periods of high demand).

- Develop a cost analysis and implement capital improvement planning.

- Develop water audits and implement leak detection programs.

- Coordinate water production/delivery with treatment process capacity.

- Install/repair automated switch for the water distribution tank.

- Adequately ventilate or sunshield all electrical and mechanical equipment in warm weather.

- Consider and, as appropriate, adopt off-peak power usage strategies.

- Utilize cold water from an off-park water source to offset chiller operation.

- Reduce friction/energy losses in pumps, fans, pipes, valves, and production wells.

- Optimize treatment processes to reduce water and energy consumption.

- The potential for solar electric generation is currently being investigated. Sulphur Springs has agreed to pay half of the cost, or $4/watt

- Install a solar water heater on the roof of the Discovery Center to offset gas usage.

- Install metering devices for the WWTP to evaluate the performance of the pumps and bio-reels.

- 1Graduate student (lead author), Dept of Civil Engineering and Engineering Mechanics, University of Arizona, email: bbilly@email.arizona.edu.

- 2Professor, Dept of Civil Engineering and Engineering Mechanics, University of Arizona, email: budhu@email.arizona.edu, tel: (520) 621-2145.

- 3Research Associate Professor, Dept of Mining and Geological Engineering, University of Arizona, tel: (520) 260-8826. Also Science and Research Manager, Arizona State Parks, email: rcasavant@azstateparks.gov

- For more information on the Kartchner WWTP Facility, contact Rob Van Zandt, Arizona State Parks Development Programs Specialist, tel: (520) 988-0155.

- Project Sponsor: Arizona Water Institute.