By Matthew Roberts, Charlie Schlinger and Steve Mead

Background

The Grand Canyon is one of the natural wonders of the world. Well-concealed behind the spectacular geology and unique flora and fauna that give this National Park distinction is the engineering wonder of providing water and wastewater services to tens of thousands of daily visitors. Across the world, providing drinking water accounts for over 2% of all energy consumed, but in this national gem, water is much more difficult to come by, accounting for nearly 25% of the energy used within the Park. This case study of the Park’s water and wastewater systems helps determine the unique challenges their operators face and provides guidance for solutions. The Grand Canyon National Park receives over 4 million visitors each year who can observe, experience, and take home sustainable living practices; the Park’s water and wastewater systems should be at the backbone of this paradigm.

Water

Supply, Treatment & Transmission

Supply, Treatment & Transmission

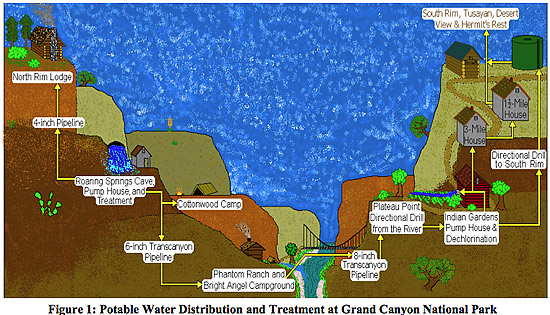

In terms of energy consumption, delivery from the source to the user is much more important than the treatment of drinking water. The supply of drinking water for most of the Park is Roaring Springs, about 4000 ft below the North Rim. Sediment is removed and chlorine gas is used for disinfection at Roaring Springs. The water then travels by gravity flow through the Trans-Canyon Pipeline (TCP) to Indian Gardens with connections at Cottonwood Campground and Phantom Ranch. The TCP crosses a suspension bridge over the Colorado River and passes through a directionally drilled borehole to Plateau Point where there is enough residual pressure to deliver water to Indian Gardens. Due to the TCP’s age, delicate condition and frequent failures, the flow is maintained constant and is not turned down, even during periods of low demand. Consequently, excess water that is not needed at the South Rim is de-chlorinated and discharged to Garden Creek. Two pipes lead from Indian Gardens delivering drinking water to the South Rim: one branch follows a directionally drilled borehole to storage tanks on the South Rim; the other branch follows the Bright Angel Trail and has connections at 3-Mile Rest House and 1 ½-Mile Rest House.

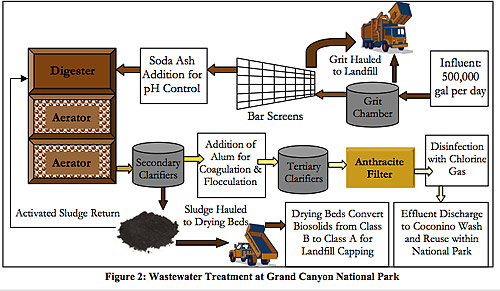

A daily average of 500,000 gallons of wastewater from South Rim facilities, hotels, housing, offices, businesses, etc., is gravity-fed to the nearby South Rim wastewater treatment plant (WWTP).

A daily average of 500,000 gallons of wastewater from South Rim facilities, hotels, housing, offices, businesses, etc., is gravity-fed to the nearby South Rim wastewater treatment plant (WWTP).

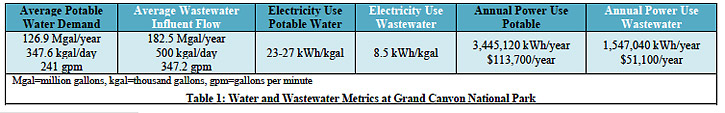

These metrics are based on the year 2007 to obtain a snapshot of the Park’s operations. The estimates for potable water pumping were based on annual figures provided from the Park. Wastewater flows were estimated by the wastewater treatment plant’s operator. Electrical usage for water and wastewater systems were developed from Arizona Public Service billing records. Natural gas consumption figures were not considered because natural gas is not directly used in the treatment of potable or wastewater.

Presented below are some best practice recommendations and suggestions that we identified as part of our qualitative evaluation.

- Assess the need of the tertiary treatment of wastewater: it is rarely done in comparable systems.

- Discuss alternatives regarding the chlorination of drinking water: using helicopters to transport chlorine gas is energy consumptive.

- Coordinate raw water production/distribution with treatment process capacity.

- Assess costs of maintaining existing facilities versus upgrading over the expected life of the system.

- Review system plans, specifications, and records with plant operators, maintenance staff, and engineers before considering upgrades/improvements.

- Evaluate costs for different available water sources.

- Secure operations and maintenance guides and training for park staff when new systems/components are installed.

- Allow the bar screen rake to rise only enough to expose more clean bar screen, letting excess water drip off before deposition in a dumpster, thereby not hauling excess water weight to the landfill.

- Implement a water conservation and education program.

- Evaluate pumps, blowers, and motors for upgrade to high-efficiency or VFD.

- Directly utilize heat in blower/pump room to keep biological activities warmer and thus more reactive or to heat nearby buildings in the winter.

- Develop a cost analysis and implement capital improvement planning.

- Reduce leakage through pressure management.

- Adopt water-efficient ordinances and codes.

- Conduct an energy audit of all pumps and blowers and their total energy consumption.

- Retrofit facilities with energy efficient lighting, using high-efficiency ballasts and bulbs.

- Perform a loss/leakage survey for both reclaimed water and influent wastewater.

- Create financial or other incentives for water users to conserve instead of increasing production/treatment capacity.

- Utilize off-peak power usage strategies.

- Adequately ventilate or sunshield all electrical and mechanical equipment in warm weather.

- Take measurements and evaluate the data prior to making future improvement plans.

- Reduce friction/energy losses in pumps, fans, pipes, valves, and production wells.

- Replace the entire TCP with a larger-diameter lower-friction-loss steel pipe that can handle washouts, increased future demands, and water pressure transients during valve closures or flow adjustments.

- Reduce pressures within the new TCP with an electric turbine to generate supplemental electricity power.

- Use a MIOX system at Roaring Springs: the system runs on salt, thus mules can safely bring in the raw materials.

- Install a hydro-electric turbine on Bright Angel Creek, near Phantom Ranch, to generate power for Phantom Ranch and to run a UV-dechlorination unit, discharging surplus water to Bright Angel Creek, which Roaring Springs normally feeds.

- Change coarse-bubble diffusers to fine-bubble diffusers to increase aeration efficiency.

- Utilize renewable energy wherever appropriate throughout the water and wastewater systems.

Please contact the authors of the study with questions about the study, supporting data, and background information: Matt Roberts (msr43@nau.edu), Charlie Schlinger (charles.schlinger@nau.edu) or Steve Mead (stephen.mead@nau.edu) at Northern Arizona University. For more information on Grand Canyon National Park, please contact Steve Rice, Hydrologist by email: steven_rice@nps.gov.

Project Sponsors: Grand Canyon National Park, Arizona Water Institute, NAU Ecological Monitoring & Assessment.